Maintenance management software is a powerful tool that can help you streamline your maintenance processes, reduce downtime, and improve overall asset management. With the right software, you can easily track work orders, schedule preventive maintenance, and manage your inventory more efficiently. Simply put, effective maintenance management can save your organization time and money, while also improving safety and reliability. So let's explore the maintenance management software features.

EnhanceMaint-CMMS, Maintenance management software is a powerful tool that can help you streamline your maintenance processes, reduce downtime, and improve overall asset performance. With the software, you can easily track work orders, schedule preventive maintenance, and manage your inventory more efficiently. Simply put, effective maintenance management can save your organization time and money, while also improving safety and reliability.

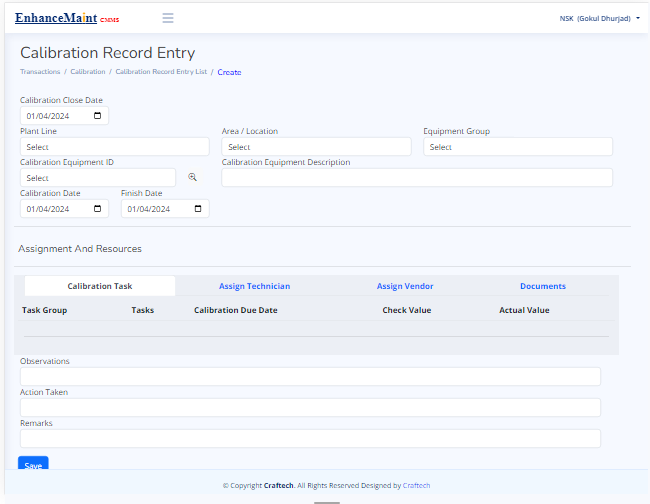

Key features of the software...

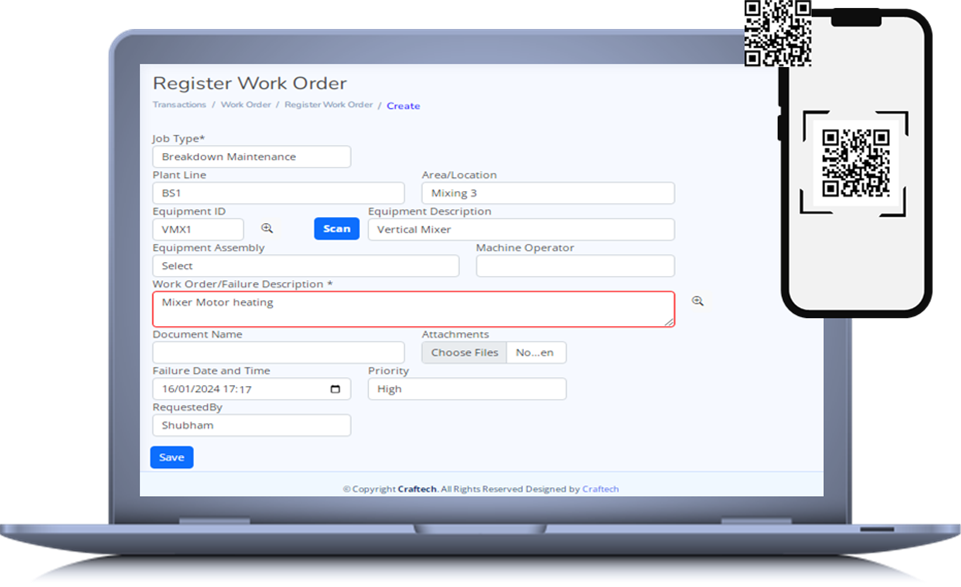

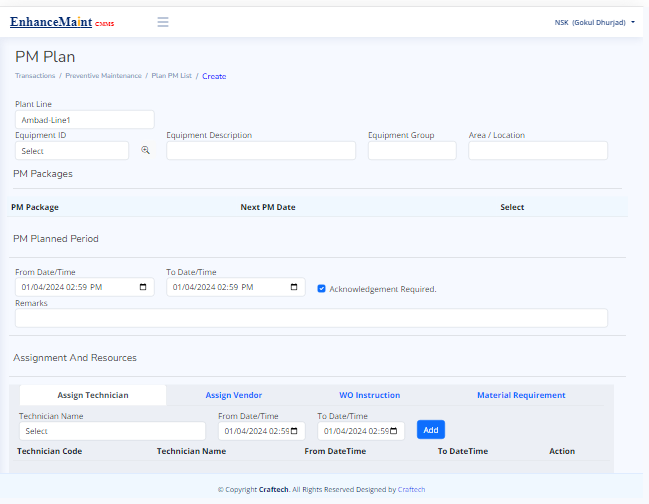

- Organize Maintenance work.

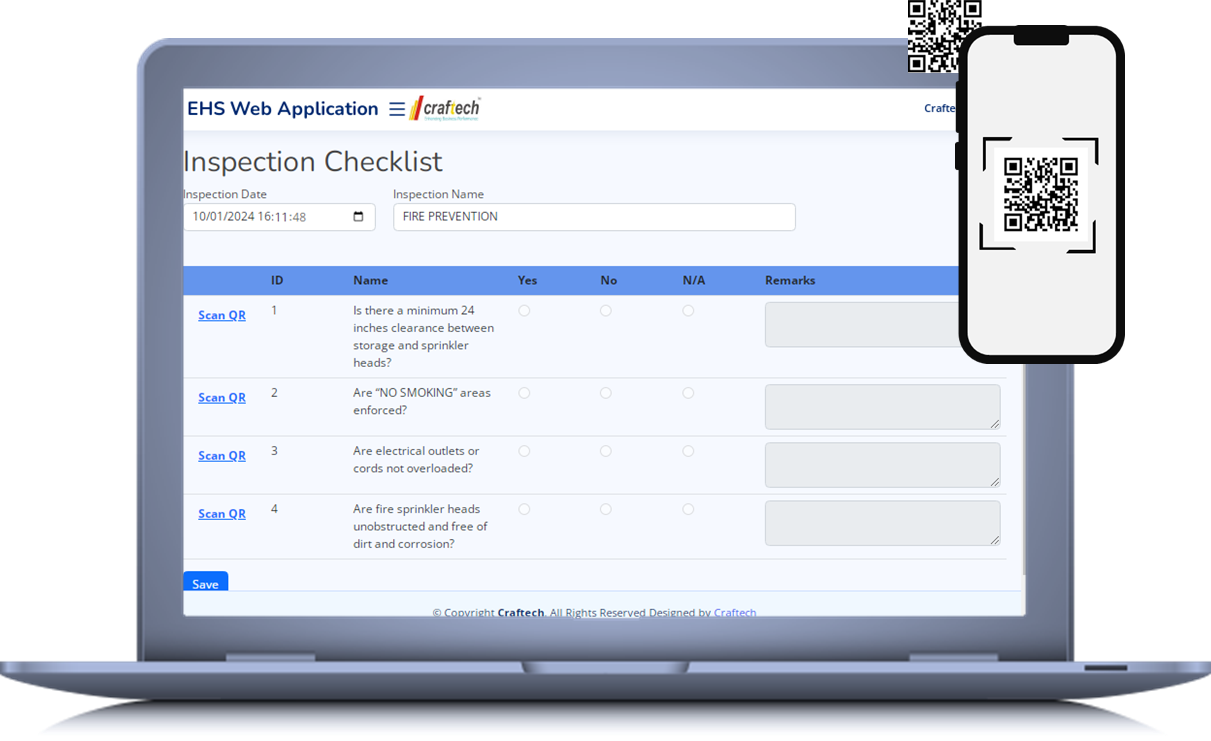

- Register and track WO by scanning QR Code

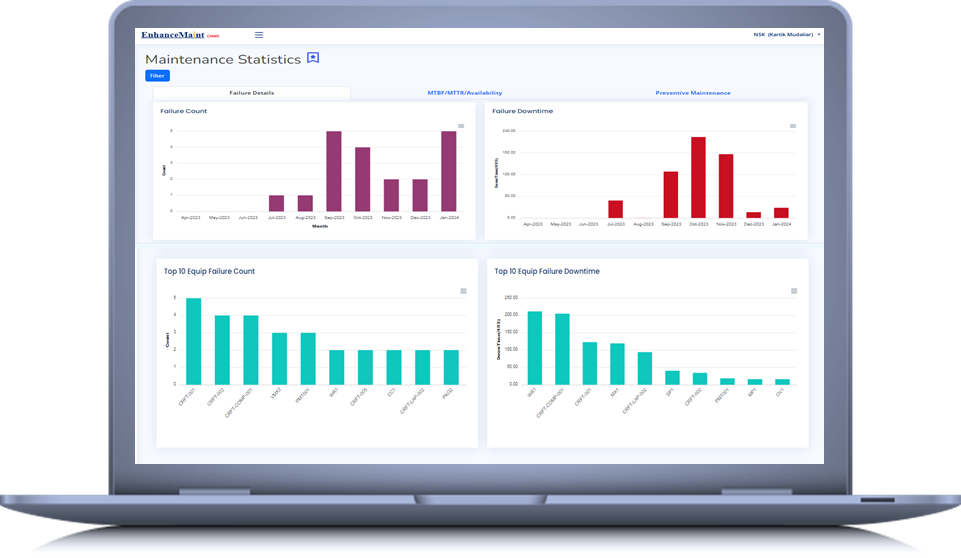

- Identify failure trends on equipment and its parts

- Rationalize PM task list (Track failure MTBF with PM frequency).

- Identify maintenance cost on asset- Material and Labor

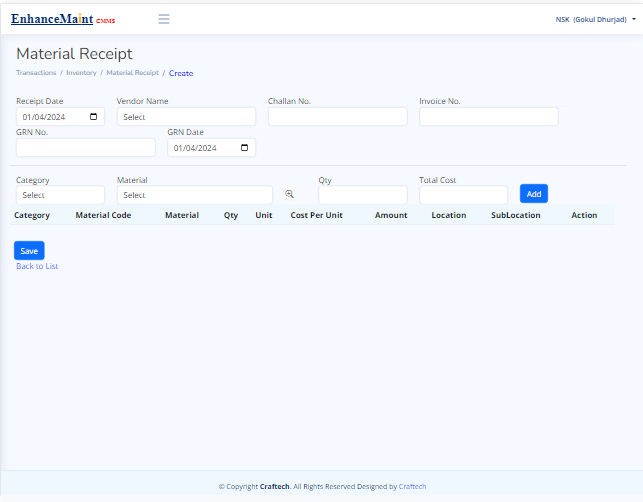

- Complete Spares management with Reports

- Attach files to (Equipment drawings, material specs, calibration certificate, etc.

- Easy and fast retrieval of maintenance data, enhancing Office efficiency

- Details maintenance history reports & equipment reliability analysis.